During more than a decade, Red Leaf’s technology division, Green Leaf Carbon Technologies, has developed and is now bringing to market a near-zero emissions technology that can ensure a positive future for industries extracting carbon-rich ores including oil shale and coal.

Technology

The world needs energy to sustain its development and raise the standard of living of billions in the developing world. At the same time, it demands that those that supply this energy effectively eliminate emissions. Using our patented, world-leading technology, Red Leaf and our technology division, Green Leaf, are at the forefront of these developments.

During over a decade of development and refinement and an investment of over $200 million in technology and resource assessment, we have secured over 30 US and overseas patents, strengthening Green Leaf’s position as an industry leader in environmentally sound oil shale technologies. We are now developing a multi-million barrel oil resource in Utah which will use the ground-breaking HCCO® (homogeneous charged continuous oxidation) process. The process is water and energy self-sufficient and essentially eliminates the emissions from production using new carbon technology. The design has been validated by our technical advisor, Hatch, a global engineering firm, which has outlined a clear path to commercialization.

Green leaf’s proprietary HCCO® process virtually eliminates the emissions from liquid fuels produced from organic-rich sources.

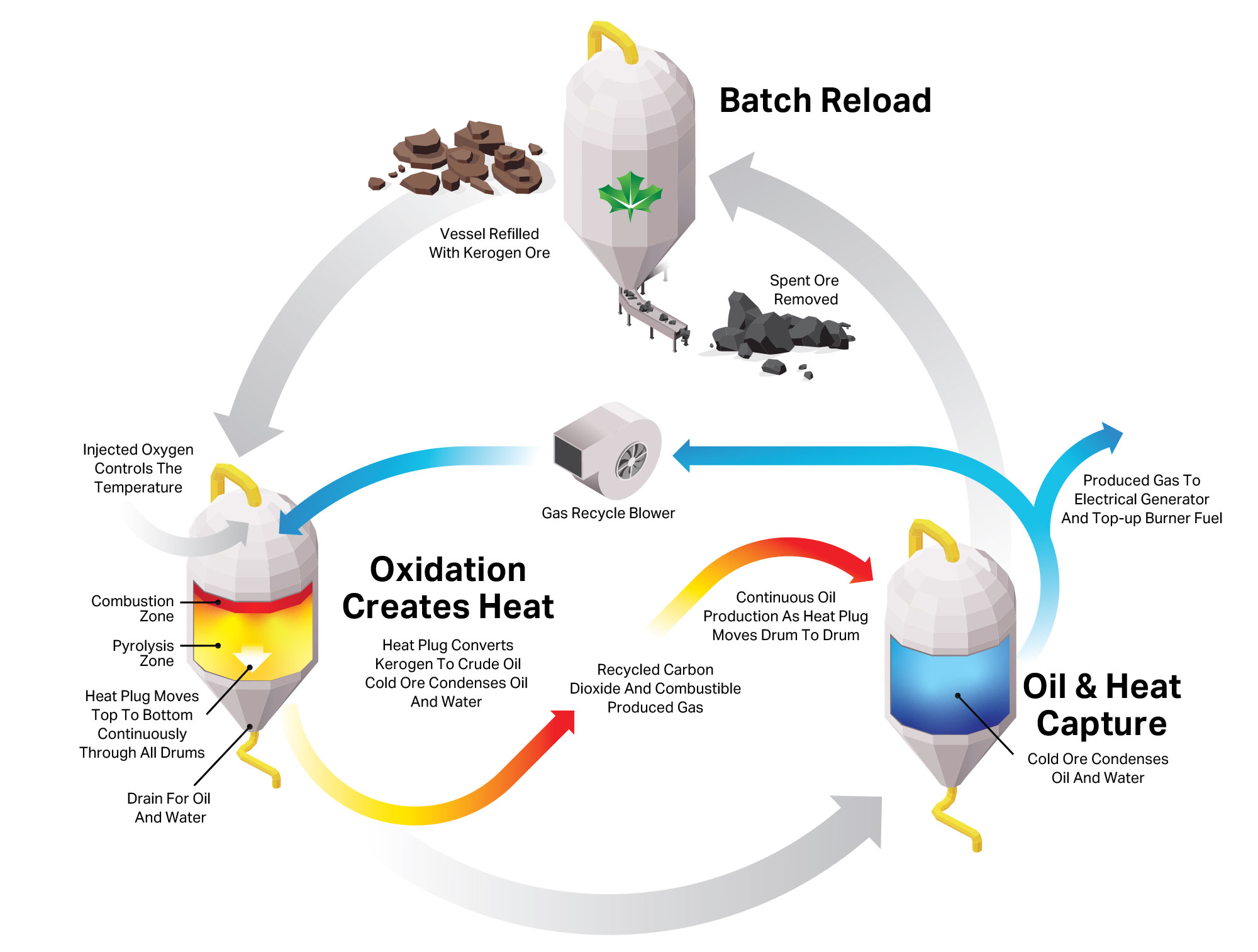

How it works

Selective mining and beneficiation of the oil shale provides a rich feedstock for the retorting process. At the same time, rare earth ores are separated out and stored for later processing. In the retort drums, the organic-rich ore is heated by controlled low-temperature oxidation of the produced hydrogen-rich gas. At the same time, heat is transferred from the gas to the rubblized shale bed. The retort drums are ganged together so the batch process of a single drum is made continuous in heat and fluid movement, gaining efficiencies from both processes. Meanwhile, cool ore beds downstream act as condensers and provide heat recovery, adding to the efficiency of the process.

Advantages

Green Leaf’s HCCO® process is a game changer that enables significant benefits beyond near-zero CO2 emissions.

The process is highly efficient and energy and water self-sufficient:

- No requirements for external fuel or power as the process generates its own hydrogen-rich gaseous fuel

- The retorting process is a net producer of water

- Batch process for ore handling but continuous for oil and gas production, heat movement and energy balance

- Elimination of air results in no NOx emissions as nitrogen is not introduced into the system

No tailings or tailings ponds required as processed spent shale is inert and can be concurrently reclaimed

Maximizes oil production and quality by optimizing operating conditions:

- Milder retort temperature and longer retort times than other processes

- Our Seep Ridge project yields ~24° API oil with significant middle distillate content

Overcomes the challenges of competing technology:

- Higher heat recovery through continuous movement of the thermal front between drums

- Minimizes the fines and aerosol problems of moving beds by using static beds

- Prevents deleterious oxygen from contacting the produced oil and gas

Concentrated CO2 generated can be sequestered or used for enhanced oil recovery (EOR) in nearby oil fields

Modular and scalable design allows development to proceed in stages, enabling capital costs to be tailored to specific project parameters